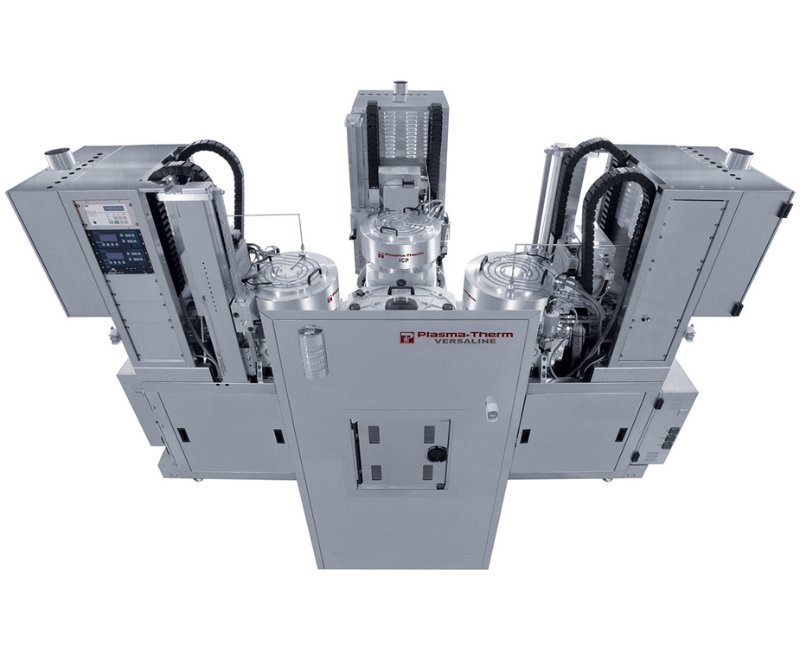

Plasma-Therm - Versaline (Etch & Deposition Processes)

Plasma-Therm's versaline platform is the workhorse for a variety of applications in specialty semiconductor markets.

Versaline system models are configured to perform an array of etch and deposition processes. Ion beam technology suits a range of applications, from low, controllable damage etching to high-rate, high-aspect-ratio, deep silicon etching to difficult materials. The systems support process control through EndpointWorks®. Enhancements include data logging, automated maintenance scheduler (AMS), and SECS/GEM. Likewise, the Cortex® control system provides a stable, user-friendly control interface designed for efficiency and productivity.

The Versaline platform’s modular design allows for flexible configuration of substrate handling for a variety of handling options, from R&D single wafer or carrier loading with a loadlock to high-volume, multi-chamber production clusters. Clear upgrade paths that leverage costs and process development make future planning easy.

Other key features include:

- LL (Loadlock for single substrate or single batch carrier. Upgradable to cassette loading)

- CX (For cassette and cluster configuration - up to 75mm to 200mm capable)

Plasma-Therm's versaline platform is the workhorse for a variety of applications in specialty semiconductor markets.

Versaline system models are configured to perform an array of etch and deposition processes. Ion beam technology suits a range of applications, from low, controllable damage etching to high-rate, high-aspect-ratio, deep silicon etching to difficult materials. The systems support process control through EndpointWorks®. Enhancements include data logging, automated maintenance scheduler (AMS), and SECS/GEM. Likewise, the Cortex® control system provides a stable, user-friendly control interface designed for efficiency and productivity.

The Versaline platform’s modular design allows for flexible configuration of substrate handling for a variety of handling options, from R&D single wafer or carrier loading with a loadlock to high-volume, multi-chamber production clusters. Clear upgrade paths that leverage costs and process development make future planning easy.

Other key features include:

- LL (Loadlock for single substrate or single batch carrier. Upgradable to cassette loading)

- CX (For cassette and cluster configuration - up to 75mm to 200mm capable)

Plasma-Therm's versaline platform is the workhorse for a variety of applications in specialty semiconductor markets.

Versaline system models are configured to perform an array of etch and deposition processes. Ion beam technology suits a range of applications, from low, controllable damage etching to high-rate, high-aspect-ratio, deep silicon etching to difficult materials. The systems support process control through EndpointWorks®. Enhancements include data logging, automated maintenance scheduler (AMS), and SECS/GEM. Likewise, the Cortex® control system provides a stable, user-friendly control interface designed for efficiency and productivity.

The Versaline platform’s modular design allows for flexible configuration of substrate handling for a variety of handling options, from R&D single wafer or carrier loading with a loadlock to high-volume, multi-chamber production clusters. Clear upgrade paths that leverage costs and process development make future planning easy.

Other key features include:

- LL (Loadlock for single substrate or single batch carrier. Upgradable to cassette loading)

- CX (For cassette and cluster configuration - up to 75mm to 200mm capable)