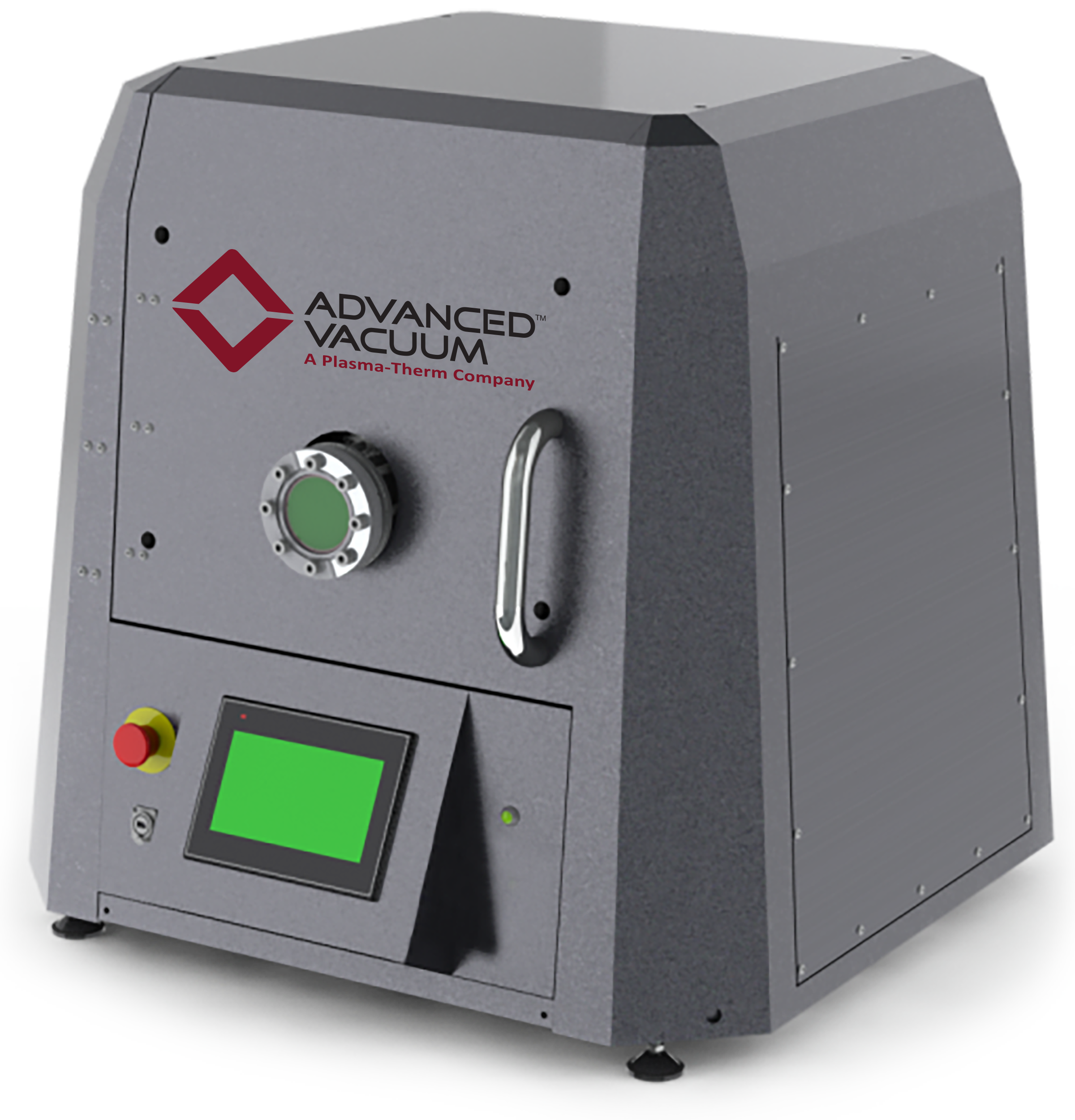

Plasma-Therm - PlasmaPOD™ - Barrel Etch (300W or 600W)

Earlier this year Plasma-Therm (Advanced Vacuum's parent company) acquired JLS Design Ltd in the United Kingdom, and with that came the PlasmaPOD™. These tools are small, compact table-top systems specifically designed for space-constrained University labs that are running Material Science courses, R&D departments of small to midscale device manufacturers who want to keep the cost of development under control, and small Failure Analysis departments where space and price are purchase constraints.

To-date, Advanced Vacuum have four broad preconfigured toolsets available;

- Reactive Ion Etch (RIE)

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Sputter Deposition (4 variations)

- Barrel Etch (2 variations)

This listing is for the PlasmaPOD™ Barrel Etch, which is available with either a 300W or 600W RF Generator and auto-matching. Addition features include:

- Stainless Steel chamber with Aluminum Faraday Cage assembly

- 2 gas lines (inc MFCs)

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer for pressure measurement

- Automatic closed-loop pressure control

- All controls are within the frame to minimize the footprint

- Built-in process recipe control and data logging

Earlier this year Plasma-Therm (Advanced Vacuum's parent company) acquired JLS Design Ltd in the United Kingdom, and with that came the PlasmaPOD™. These tools are small, compact table-top systems specifically designed for space-constrained University labs that are running Material Science courses, R&D departments of small to midscale device manufacturers who want to keep the cost of development under control, and small Failure Analysis departments where space and price are purchase constraints.

To-date, Advanced Vacuum have four broad preconfigured toolsets available;

- Reactive Ion Etch (RIE)

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Sputter Deposition (4 variations)

- Barrel Etch (2 variations)

This listing is for the PlasmaPOD™ Barrel Etch, which is available with either a 300W or 600W RF Generator and auto-matching. Addition features include:

- Stainless Steel chamber with Aluminum Faraday Cage assembly

- 2 gas lines (inc MFCs)

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer for pressure measurement

- Automatic closed-loop pressure control

- All controls are within the frame to minimize the footprint

- Built-in process recipe control and data logging

Earlier this year Plasma-Therm (Advanced Vacuum's parent company) acquired JLS Design Ltd in the United Kingdom, and with that came the PlasmaPOD™. These tools are small, compact table-top systems specifically designed for space-constrained University labs that are running Material Science courses, R&D departments of small to midscale device manufacturers who want to keep the cost of development under control, and small Failure Analysis departments where space and price are purchase constraints.

To-date, Advanced Vacuum have four broad preconfigured toolsets available;

- Reactive Ion Etch (RIE)

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Sputter Deposition (4 variations)

- Barrel Etch (2 variations)

This listing is for the PlasmaPOD™ Barrel Etch, which is available with either a 300W or 600W RF Generator and auto-matching. Addition features include:

- Stainless Steel chamber with Aluminum Faraday Cage assembly

- 2 gas lines (inc MFCs)

- Internal PLC control system

- Touch-screen interface

- Capacitance manometer for pressure measurement

- Automatic closed-loop pressure control

- All controls are within the frame to minimize the footprint

- Built-in process recipe control and data logging