Corial - 200I Inductively Coupled Plasma/ICP-RIE Etch System

Industry-leading uniformity for etching silicon-based compounds and polymers.

The Corial 200I ICP-RIE system is designed for R&D centers and IC failure analysis labs. This equipment uses fluorine- and oxygen-based chemistries to provide leading edge etch rates and uniformities for full wafers of up to 200 mm, as well as dies or packaged dies. Featuring a short pump-down cycle (<3 minutes), rapid reactor clean time (<20 minutes), and shuttle loading direct on the carrier, the Corial 200I guarantees high system uptime.

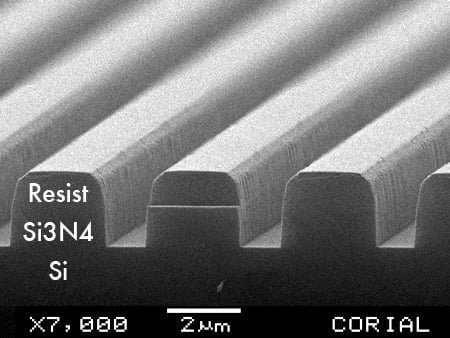

Typical materials that can be processed with the Corial 200I ICP-RIE system include:

- Silicon and silicon-based compounds (SiO2, Si3N4)

- Polymers: PMMA, Polyimide, BCB, Photoresist

- Metals: Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, Nbn, Mo

The Corial 200I also offers differentiated technology and application-focused capabilities for the IC failure analysis and the R&D markets:

- Delayering of polymers and silicon-based compounds for sample preparation prior to IC failure analysis

- Capability to etch the wide range of materials used in R&D centers

Industry-leading uniformity for etching silicon-based compounds and polymers.

The Corial 200I ICP-RIE system is designed for R&D centers and IC failure analysis labs. This equipment uses fluorine- and oxygen-based chemistries to provide leading edge etch rates and uniformities for full wafers of up to 200 mm, as well as dies or packaged dies. Featuring a short pump-down cycle (<3 minutes), rapid reactor clean time (<20 minutes), and shuttle loading direct on the carrier, the Corial 200I guarantees high system uptime.

Typical materials that can be processed with the Corial 200I ICP-RIE system include:

- Silicon and silicon-based compounds (SiO2, Si3N4)

- Polymers: PMMA, Polyimide, BCB, Photoresist

- Metals: Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, Nbn, Mo

The Corial 200I also offers differentiated technology and application-focused capabilities for the IC failure analysis and the R&D markets:

- Delayering of polymers and silicon-based compounds for sample preparation prior to IC failure analysis

- Capability to etch the wide range of materials used in R&D centers

Industry-leading uniformity for etching silicon-based compounds and polymers.

The Corial 200I ICP-RIE system is designed for R&D centers and IC failure analysis labs. This equipment uses fluorine- and oxygen-based chemistries to provide leading edge etch rates and uniformities for full wafers of up to 200 mm, as well as dies or packaged dies. Featuring a short pump-down cycle (<3 minutes), rapid reactor clean time (<20 minutes), and shuttle loading direct on the carrier, the Corial 200I guarantees high system uptime.

Typical materials that can be processed with the Corial 200I ICP-RIE system include:

- Silicon and silicon-based compounds (SiO2, Si3N4)

- Polymers: PMMA, Polyimide, BCB, Photoresist

- Metals: Ti, TiN, TiW, W, Ta, TaN, Ge, Nb, Nbn, Mo

The Corial 200I also offers differentiated technology and application-focused capabilities for the IC failure analysis and the R&D markets:

- Delayering of polymers and silicon-based compounds for sample preparation prior to IC failure analysis

- Capability to etch the wide range of materials used in R&D centers